Why Investing in TRUMPF Machines Boosts Efficiency and Quality

In the evolving world of steel fabrication, precision and productivity determine success. For local fabrication companies that want to stay competitive, investing in world-class machinery is essential. At Fabtech Steel, a division of Fabtech Export Industries Inc., we continuously raise the bar by integrating advanced TRUMPF machines into our steel fabrication plant—delivering quality that meets international standards.

1. Precision That Defines Excellence

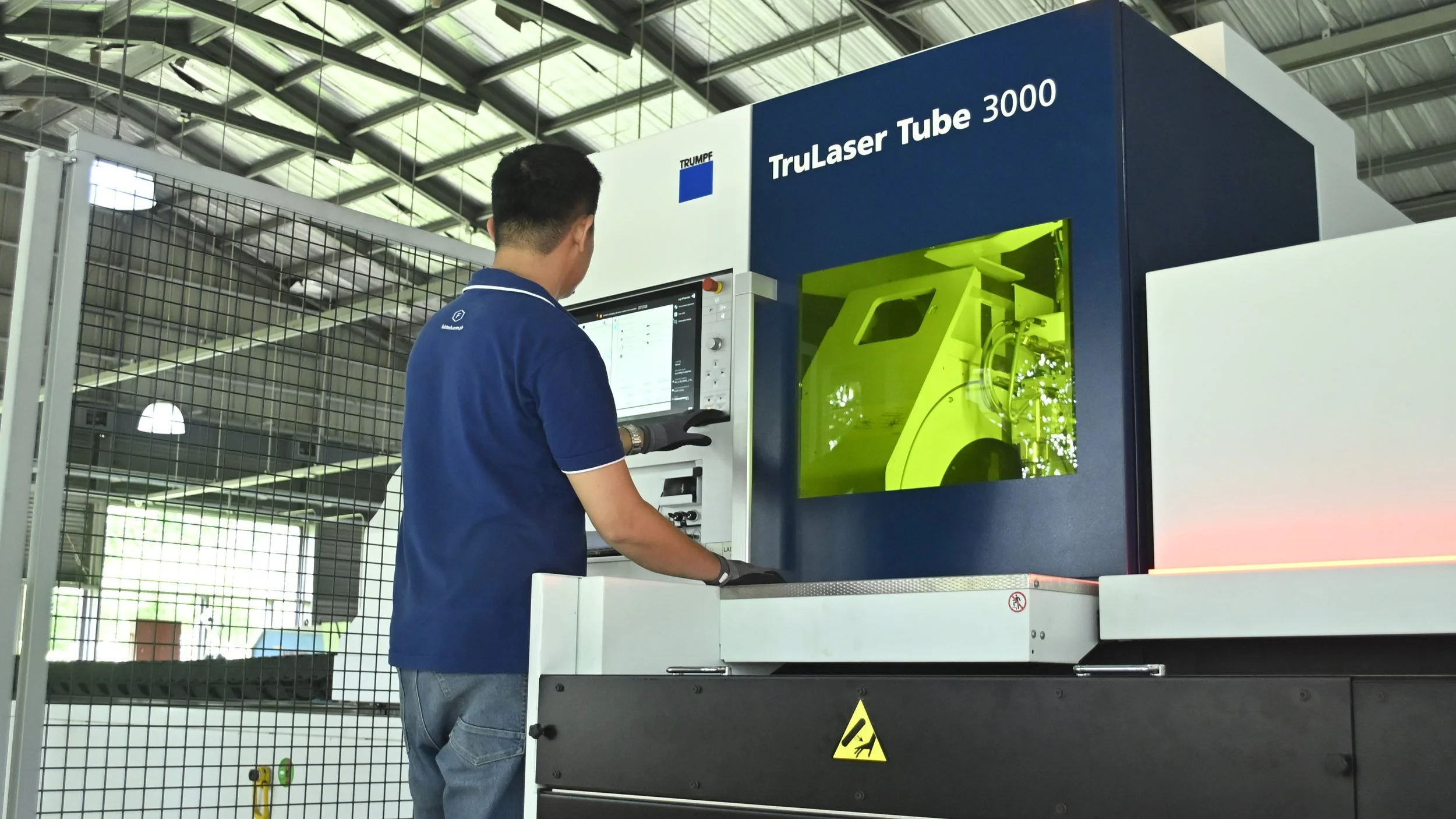

Worker operating TRUMPF TruLaser Tube 3000 for precision laser tube cutting in a steel fabrication facility.

TRUMPF laser and punching technologies are known for their accuracy and consistency. Whether cutting mild steel or stainless steel, each component is crafted with exact precision, reducing waste and minimizing rework. This level of detail allows Fabtech Steel to meet the strictest specifications across architectural, industrial, and infrastructure projects.

2. Faster Production, Greater Efficiency

Workers loading a steel sheet into the TRUMPF TruBend 5130 press brake during the metal bending process.

Efficiency is at the core of modern stainless steel fabrication. TRUMPF machines feature automated material handling and high-speed cutting systems that shorten production time without sacrificing accuracy. By streamlining processes within our steel fabrication plant, we ensure faster turnaround and more consistent quality for our clients.

3. Smart Automation for Local Fabrication

Close-up of TRUMPF fiber laser cutting steel with high-precision technology.

Beyond cutting-edge mechanics, TRUMPF integrates seamlessly with Industry 4.0 systems—allowing our team to monitor production in real time, manage maintenance schedules, and optimize workflow. This makes Fabtech Steel one of the few local fabrication companies in the Philippines embracing truly smart manufacturing solutions.

4. Uncompromised Quality and Reliability

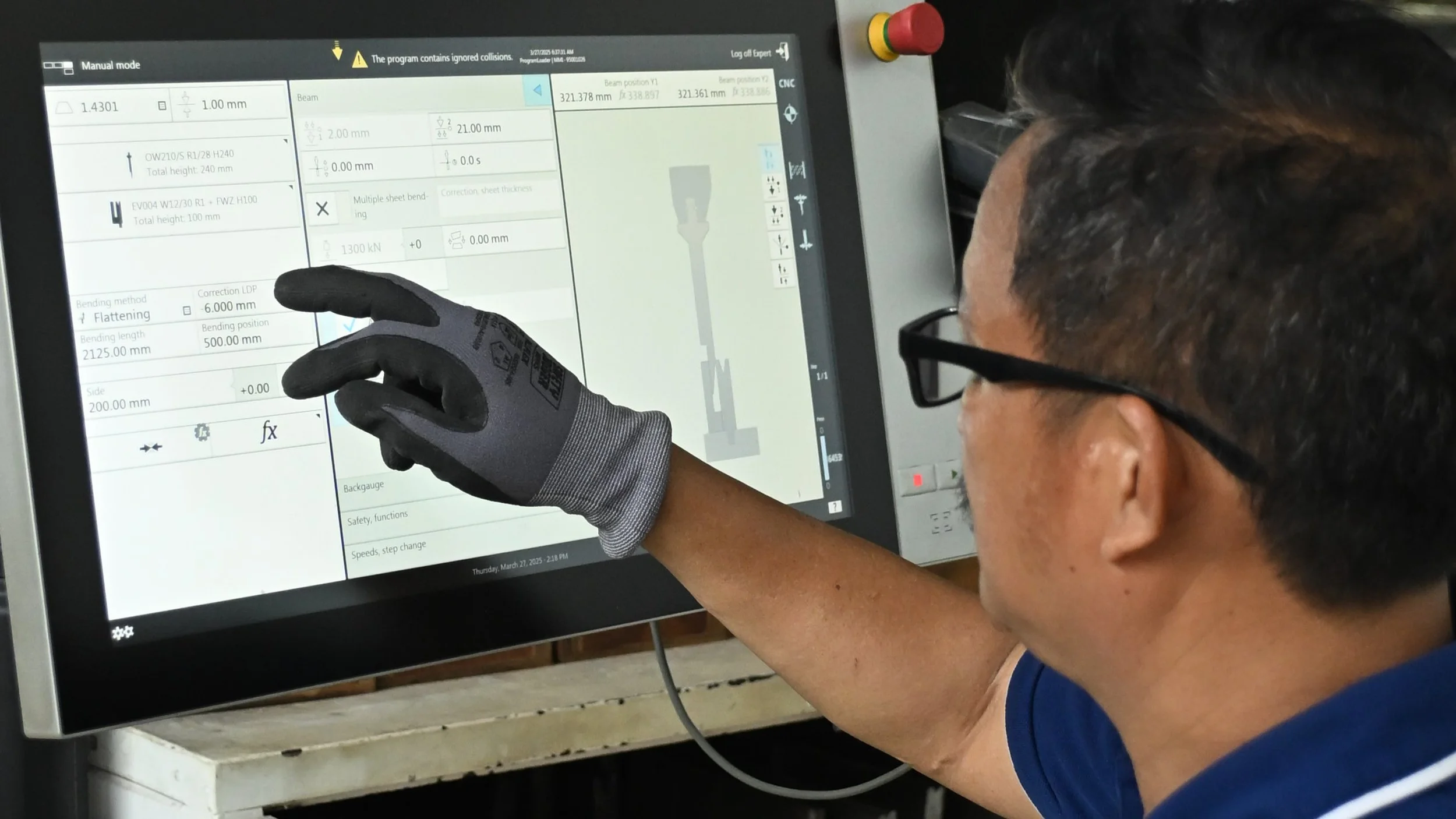

Close-up of a worker operating a TRUMPF machine, adjusting settings on the control monitor for accurate fabrication.

Every project we deliver is backed by the dependability of TRUMPF technology. From custom components to full-scale stainless steel plant systems, Fabtech ensures that every product meets the highest quality standards. Our goal is simple: to give clients confidence in every structure we build.

5. Long-Term Investment, Lasting Value

Full shot of the TRUMPF TruMatic 6000 laser-punch combination machine used for advanced steel fabrication.

While advanced machinery requires a higher upfront investment, TRUMPF systems offer exceptional long-term value. Reduced downtime, consistent accuracy, and lower maintenance costs result in a higher return on investment. At Fabtech Export Industries Inc., we see TRUMPF as more than a machine—it’s a partner in sustainable growth and innovation.

Fabtech Steel: Powering the Future of Fabrication in the Philippines

As part of Fabtech Export Industries Inc., Fabtech Steel brings the precision of TRUMPF technology to the Philippine steel fabrication industry. With machines like the TruLaser Tube 3000 Fiber, we deliver projects that combine speed, strength, and superior quality—proving that world-class fabrication can be done right here at home.